Watch out for Emulsions and Schmoo & Ensure Your Levels are Right!

The new generation of level measurement

Modern hydrocarbon production comes from more than 60% from producing fields that are over 20 years old1. One of the major problems with hydrocarbon production is the high water quantity associated with this extraction. Water to oil ratio from oil fields are in average 3:12, meaning that for every barrel of oil produced, there will be 3 barrels of water accompanying the crude oil. At the same time, the total global extraction of produced water is rising.

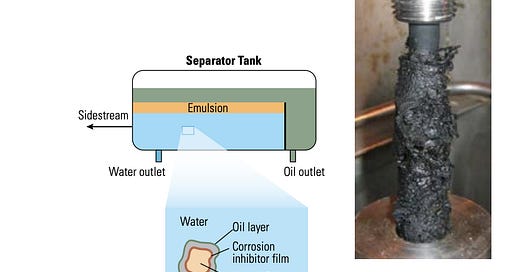

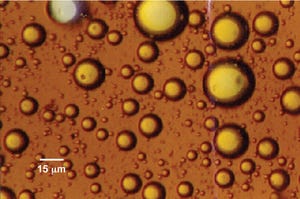

So with a high amount of water present, and oil and water being two immiscible3 fluids there is a high likelihood for emulsion formation due to the agitation, turbulent flow4 conditions and mixing energy present in the system causing a diffusion of one liquid into the other. The presence of emulsifying agents such as asphaltenes5 and resin6 increase the emulsion formation.

Petrowiki7 , describes oil emulsions as:

“An emulsion is a dispersion (droplets) of one liquid in another immiscible liquid. The phase that is present in the form of droplets is the dispersed or internal phase, and the phase in which the droplets are suspended is called the continuous or external phase. For produced oilfield emulsions, one of the liquids is aqueous and the other is crude oil. The amount of water that emulsifies with crude oil varies widely from facility to facility. It can be less than 1% and sometimes greater than 80%.”

Why emulsions matter, is that they play a certain role in the production and transportation of the hydrocarbon production, that cannot be neglected. Furthermore the emulsions also facilitate the build up of corrosion that also can lead to unexpected shutdowns and leakages.

In hydrocarbon production, separators are used to separate the various phases, i.e. separating a well stream into gaseous and liquid components. Separators carry a significant functional role in meetings stringent requirements for the separated phases. As stated in Petrowiki8 :

Oil must have less than 1% (by volume) water and less than 5 lbm water/MMscf gas.

Produced water stream must have less than 20 ppm oil for overboard discharge in the Gulf of Mexico (GOM).

So the emulsions can and do have a negative effect on the separator efficiency. Also, in separators, you can find the buildup of “schmoo”9 - In almost any gas, oil and water-producing stream solids will be present. These solids can get coated with oil, meaning that they are buoyant and can travel long distances in the processing systems. Some treating chemicals are surface active and are strongly attracted to the solids, which in turn attract further oil, asphaltenes, bacteria, paraffins etc, making the solid particles very sticky and effectively coating any process equipment it encounters, including measurement devices and instrumentation.

Separators are relying on various instrumentation for level controlling, the most readily available parameter to control their behavior, impacting the performance. When the levels are outside their set ranges, there are alerts, alarms or automated process shutdowns. This is to protect machines, equipment but foremost for the safety, security, occupational health and environmental aspects. So the level instrumentation is crucial to function with high reliability, have a high performance and be able to work under harsh conditions, where even this type of equipment will with high probability have to endure conditions with emulsions and surface contaminations. No wonder that level instrumentation and controllers are cause for more than 70% of reported separator failures10.

That’s why robust and reliable performance of level profiling instruments is a highly important area to highlight and ensure the proper functionality.

ROCSOLE11, the Finnish tech company, with its’ own patented technology, has developed and launched a new generation of level profiling solutions12, ensuring frequent data even having surface contamination, as this is one of the key issues with legacy technology.

Not only does the device work with a contamination, it also registers data near real-time, providing operators an important tool for reliable process control and automation. Such tools are crucial in terms of reducing operational risks, costs and to ensure safe operations that also enables lowering the carbon footprint. Production optimization has been evaluated as one key parameter in reducing overall carbon emissions13.

For such a complex operating environment with extremely challenging conditions, the implementation and use of proven best technology will be important.

https://www.ep.total.com/sites/g/files/wompnd1021/f/atoms/files/07_mature_fields_en.pdf

Arabian Journal of Chemistry, January 2020, Article” Overview on petroleum emulsions, formation, influence and demulsification treatment techniques”, https://www.sciencedirect.com/science/article/pii/S1878535218302442

Immiscible: Immiscibility is the property where two substances are not capable of combining to form a homogeneous mixture such as oil and water. The components are said to be "immiscible!”. https://www.thoughtco.com/definition-of-immiscible-and-example-605237#:~:text=Immiscibility%20is%20the%20property%20where,will%20separate%20from%20each%20other.

Turbulent flow: https://www.britannica.com/science/turbulent-flow

Asphaltene: https://en.wikipedia.org/wiki/Asphaltene

Resin: https://en.wikipedia.org/wiki/Resin

https://petrowiki.spe.org/Oil_emulsions#:~:text=An%20emulsion%20is%20a%20dispersion,the%20continuous%20or%20external%20phase.

https://petrowiki.spe.org/Oil_and_gas_separators#:~:text=Depending%20on%20a%20specific%20application,from%20the%20bulk%20liquid%20stream.

https://www.slb.com/-/media/files/oilfield-review/03-corrosion-english

JPT “Savvy Separator: Level Design and Control in Gravity Separators” https://jpt.spe.org/level-design-and-control-gravity-separators

www.rocsole.com

https://www.linkedin.com/posts/rocsole_rocsole-profiler-with-uneven-deposits-activity-6788424157790007296-BiZP

McKinsey report: https://www.mckinsey.com/~/media/McKinsey/Industries/Oil%20and%20Gas/Our%20Insights/Toward%20a%20net%20zero%20future%20Decarbonizing%20upstream%20oil%20and%20gas%20operations/Toward-a-net-zero-future-Decarbonizing-upstream-oil-and-gas-operations-vF.pdf